Cleaning and Maintaining Your Tamiya Mini 4WD Cars

A Practical, Real-World Guide From One Mini 4WD Racer To Another

If you're competitive with your Tamiya Mini 4WD cars, you already know this truth: they may be simple machines, but they reward attention to detail. A well-maintained Mini 4WD doesn’t just run smoother - it runs more consistently and can save you money over time.

This article is a deep, practical walk-through of how I clean and maintain my Mini 4WD cars. It’s not about being obsessive or overcomplicating things - it’s about building habits that keep your cars reliable, race-ready and fun to run.

Why Maintenance Matters

In the grand scheme, Mini 4WD cars don’t have a lot of moving parts - but that doesn’t mean maintenance is optional. These cars rely on efficiency, with every bit of drag showing up in increased lap times and every loose screw as inconsistency.

Maintenance helps you:

- Keep performance predictable

- Extend the life of motors, bearings and rollers

- Catch failures before they ruin a race day

- Understand your car better

Think of maintenance as part of the hobby, not a chore. Once you build a rhythm, it becomes relaxing and, honestly, quite satisfying.

Start With a Full Visual Inspection

Before tools come out or parts get removed, I always start with a simple inspection. This takes a couple of minutes and often tells you exactly what needs attention.

What I Look For First

Chassis Condition

Check for cracks around:

- Motor mounts

- Axle holes

- Bumper mounting points

- Side chassis wings

Even hairline cracks can change how a car behaves. If the chassis flexes more than it should, rollers won’t stay square and gear mesh can shift under load.

Loose Screws

Grab a driver and gently check every screw. Don’t just tighten blindly - feel for screws that won’t snug down. That usually means stripped plastic.

Bent or Misaligned Parts

Spin the car slowly in your hands and look from the front and rear. Rollers should be parallel. Wheels should sit square. If something looks “off,” it probably is.

Another simple test I use is to stand the car on its side (on the rollers) and see if the balance is good. I also give it a slight push - the car should roll freely and at a slight arc (due to the front rollers being angled). If it doesn't stay on its side (or rolls in a straight line), something is bent or broken - time for further inspection.

Note: Unfortunately, this testing procedure doesn't work with a Box Stock car.

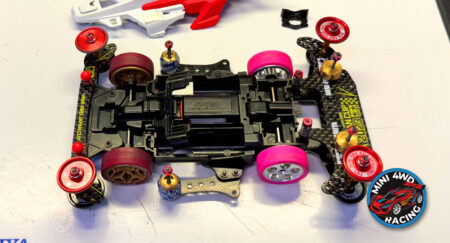

Disassembly: How Far Should You Go?

You don’t need to tear the car down to the bare chassis every time. I like to think in three levels:

- Quick clean – Between race nights

- Standard service – Every few race sessions

- Full teardown – After a big event or hard crash

For most people, a standard service is the sweet spot.

At minimum, I usually remove:

- Wheels, tires and axles - to clean the bearings or bushings

- Rollers - to clean the bearings or bushings

- Motor - to check the gears and motor condition

This gives you access to the parts that affect performance the most.

Bearings: Cleaning, Inspecting and Deciding When to Replace

If your car uses ball bearings, they deserve special attention.

Removing Bearings Safely

Use a proper bearing removal tool if you have one. If not:

- Gently push from the opposite side with something slightly larger than the axle hole

- Avoid prying with screwdrivers

- Never force a bearing that doesn’t want to move

Damaging the bearing can permanently ruin it and cause a severe loss in performance.

Cleaning Bearings

Here’s my basic process:

- Place bearings in a small glass or metal container (I like to use CowRC's Ultrasonic Cleane)

- Add motor cleaner or isopropyl alcohol

- Gently agitate for a minute or two

- Remove and set on a paper towel to fully air dry

Do not use water (this causes rust) and certainly don't blast with compressed air at close range.

To Oil or Not to Oil?

General Mini 4WD rule:

- A tiny drop of light oil is enough (I like the 1UP Racing Bearing Oil)

- Too much oil attracts dirt and slows things down

If the bearing still feels gritty after cleaning, it’s probably damaged. Bearings are wear items. Don’t try to save the bad ones.

Axles, Wheels and Tire Care

This is where a lot of speed gets lost without people realizing it.

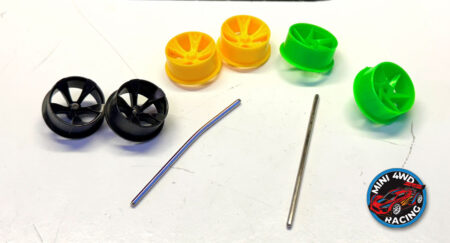

Axle Inspection

Remove each axle and roll it on a piece of glass or a setup board. If it wobbles, replace it. Bent axles:

- Create vibration

- Increase rolling resistance

- Wear bushings and bearings faster

They’re cheap. Don’t overthink it.

Wheel Condition

Check wheels for:

- Cracks around the mounting point

- Ovalized axle holes

- Wheel warping

If a wheel slides on and off the axle too easily, it’s already worn. Replace it.

Tire Maintenance

Tires are consumables. Accept it early.

What I check:

- Flat spots

- Uneven wear

- Easily sliding off the wheels

Clean tires with:

- Masking tape (for dust and fuzz)

- Mild cleaner, if rules allow

Note: If a tire slides off the wheel easily, you can use a very thin double-sided tape to keep it in place.

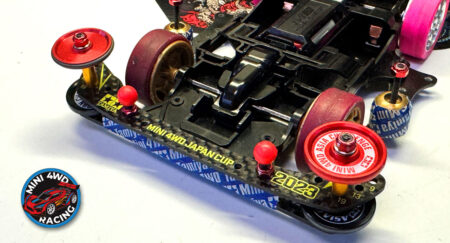

Rollers: Small Parts, Huge Impact

Rollers take abuse. Walls, jumps, landings - it all shows up here - especially with the plastic rollers.

Spin Test Every Roller

Spin the mounted roller and listen (and feel) for:

- Roughness

- Binding

- Excessive side-to-side play

A roller that doesn’t spin freely is just causing extra drag on the track.

Check Roller Faces

Look closely at the contact surface:

- Flat spots mean it’s time to replace

- Grooves can grab walls instead of rolling

- Sharp edges can damage tracks

No amount of maintenance fixes physical wear.

Hardware Matters Too

Bent screws, worn spacers and mushroomed ends can all cause misalignment and binding. Replace hardware before it becomes a problem.

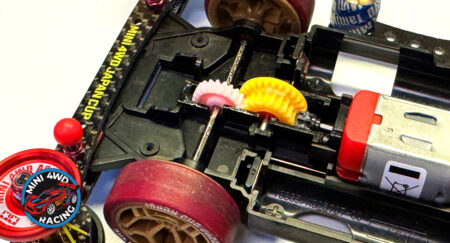

Gears and Drivetrain Cleaning

You don’t need grease everywhere. In fact, too much grease is worse than none.

Cleaning Gears

- Wipe old grease off with a lint-free cloth

- Use a soft brush for stubborn debris

- Inspect for chipped or rounded teeth

Plastic gears are tough, but they’re not immortal.

Re-Lubrication

If you lubricate:

- Use very small amounts

- Apply only where needed

- Avoid flinging grease onto tires or bearings

As a general note, a quiet drivetrain is usually a healthy one.

Motor Maintenance: Keeping Power Consistent

Motors are another wear item, but you can get good life out of them with basic care.

Cleaning the Motor

If rules allow:

- Spray motor cleaner through the vents

- Spin the shaft gently while spraying

- Let dry completely

This removes carbon dust and debris that cause drag and heat.

Shaft and Pinion Check

- Make sure the pinion is secure

- Look for wobble in the shaft

- Check for unusual noises

A noisy motor often means internal wear.

Know When to Retire a Motor

When a motor:

- Runs noticeably hotter

- Is suddenly a LOT faster than it used to be

- Sounds rough even after cleaning

…it’s probably done. Keep it for testing or practice and move on.

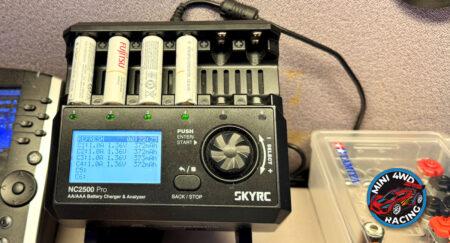

Battery Maintenance: Always Important, Often Ignored

Batteries are the heart of your Mini 4WD car. Treat them well.

Charging Habits

- Use a quality charger

- Avoid overcharging and excessive heat

- Let batteries cool before recharging

Heat is the enemy of battery life. Adding a fan on your charger will certainly help keep temps down during the charging process, especially if you charge at a high amp rate.

Matching and Rotation

As a general note, the first run on NiMh batteries (on race night) is usually when they're the best. During subsequent runs, power will fall off slightly. However, if you race seriously:

- Use matched pairs (cells that have similar voltage output)

- Rotate sets evenly

- Label batteries by age

Consistency matters more than peak voltage.

Storage

NiMh batteries can form a 'memory' and, over their lifetime, start to lose power each time they are used. Here's some general storage rules:

- Discharge completely at the end of a race night

- Store in a cool, dry place

- Keep away from direct sunlight

Old batteries that won’t hold voltage should be recycled, not forced into service.

Reassembly and Final Checks

Once everything is clean and inspected:

- Reassemble slowly

- Double-check alignment

- Once installed, spin the drivetrain and rollers by hand

I always do a final “free roll” test. Push the car gently on a flat surface (motor not installed). It should roll smoothly and straight. If it doesn’t, something still needs attention.

Final Thoughts

Maintaining Mini 4WD cars is part of what makes the hobby rewarding. It’s hands-on, practical and deeply satisfying when you see the results on track. A clean, well-maintained car doesn’t just run faster - it runs consistently and the way you expect it to.

Take your time. Enjoy the process. And remember: the fastest car is usually the one that’s been cared for the best.